1. Etching of aluminum foil

Aluminum foil is the main material of aluminum electrolytic capacitor. Set aluminum foil as anode. After being electrified in the electrolyte, an oxide film (Al2O3) will be formed on the surface of aluminum foil. The function of this oxide film is dielectric. The role of etching is to expand the surface area of aluminum foil. Etching is an electrochemical process of applying AC or DC current in chloride solution.

2. Into

Formation is the process of forming a dielectric layer (Al2O3) on the surface of anodic aluminum foil. Formed aluminum foil is generally used as anode.

In order to expand the surface area, the aluminum foil material is placed in chloride aqueous solution for electrochemical etching. Then, after applying a voltage higher than the rated voltage in the ammonium borate solution, a dielectric oxide layer (Al2O3) is formed on the surface of the aluminum foil. This dielectric layer is a very thin and dense oxide film, about. 1~1.5nm/volt, and the insulation resistance is about 108~109 Ω/m. In order to increase the efficiency of expanding the surface area, the etching shape is different according to the rated voltage.

3. Cropping

Cut the aluminum foil (cathode foil and anode foil) and electrolytic paper to the required size according to the size requirements of different products.

4. Winding

Insert electrolytic paper between the cathode foil and the anode foil, and then wind it into a cylindrical shape. In the winding process, the cathode foil and the anode foil are connected with terminals. Electrolytic paper mainly plays the role of balancing the distribution of electrolyte and maintaining the spacing between cathode foil and anode foil.

5. Immersion

Immersion is the process of immersing the prime into the electrolyte. The electrolyte can further repair the dielectric layer. Electrolyte is a liquid conducting by ions, which is a real cathode and plays a role in connecting the dielectric layer on the surface of anode aluminum foil. The cathode aluminum foil acts as a collector to connect the real cathode and the internal circuit. Electrolyte is the key material that determines the characteristics of capacitor (temperature characteristics, frequency characteristics, service life, etc.).

6. Sealing

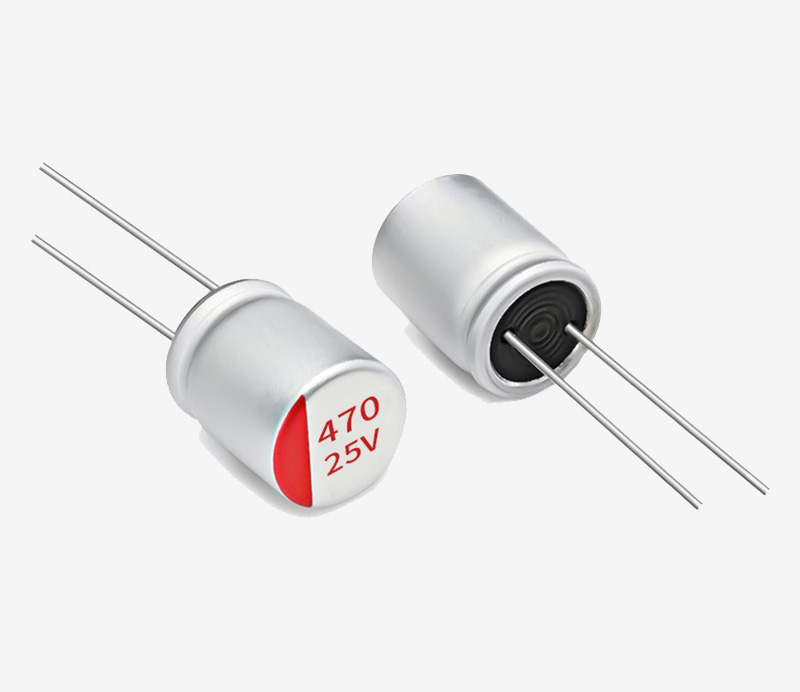

Sealing is the process of packing the element into the aluminum shell and sealing it with sealing materials (rubber, rubber cover, etc.). The main function of aluminum shell and sealing material made of rubber is to maintain the air tightness of capacitor.

7. Aging

Aging is the process of applying voltage to the sealed capacitor at high temperature. This process can repair some damage of the dielectric layer during the cutting and winding process.

8. Full inspection, packaging

After aging, the electrical characteristics of all products will be checked. Terminal processing, etc. Finally, package.

公司座机:0755-27835876

业务咨询:13532355515(陈先生)15811812283(梁先生)13714164844(卓先生)13318187223(梁先生)15013538836(林先生)

技术支持:13602632983(Mr. Liang)

公司传真:0755-27835876

地址:5/F, Block B, Yongli Industrial Center, Xixiang, Bao'an District, Shenzhen